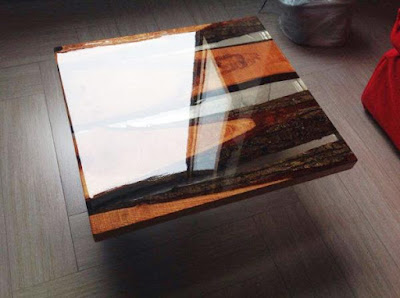

Epoxy resin for the aquarium - an all-purpose weapon?

Anyone who has ever looked into the forums on the subject of aquaristics, there is often the reference to epoxy resin. Not only the glass panes can be connected to it, but above all additional components made of polystyrene or styrofoam can be built thanks to epoxy resin in any desired shape and size for your own aquarium. Epoxy resin and its applications Epoxy resin can seal both metal and wood as well as mineral substrates such as tile adhesive. After complete drying, the surface is completely hard and even has a good impact resistance. Here are some more applications : Aquarium and terrarium boat building Motorsport Food industry Bathrooms and swimming pools Metallkleber Mortar for stone carpets Architecture in the aquarium Epoxy resin is completely solid and releases no chemical substances after curing. This makes it ideal in the aquarium to use home-made accessories. Entire landscapes of Styrofoam or polystyrene can be created, which then enrich the life as