Coloring epoxy resin

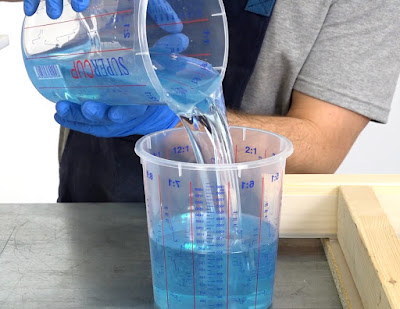

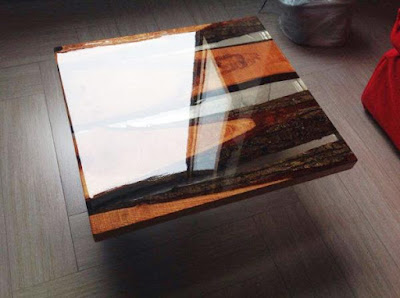

Coloring epoxy resin - instructions The terms epoxy, resin and casting resin usually hides epoxy resin. The most versatile way of tinting this versatile material is with the color pigments , color pastes or concentrates intended by the manufacturer . Then it is ensured that the special composition is coordinated. But even experiments with other colors are often worthwhile. Especially when it expands the spectrum of possibilities. As always when experimenting there are more or less successful results and often unexpected effects even with small deviations. Since the commercially available epoxy resins and hardeners differ, we recommend in any case before a larger application to make an attempt with their own starting materials. This is worth it because the material is not cheap and at the same time your own ideal mixture can be found. How can you dye in epoxy resin? Color Pastes for Epoxy Resin, Color Powder and Other Epoxy Dyes: With a starter kit, each